Due to its cheap price and durable characteristics, denim or jeans has been more and more popular, even sell well than any other kind of trousers in the whole world.

Nowadays, denim has developed into many patters, then do you know its production process?

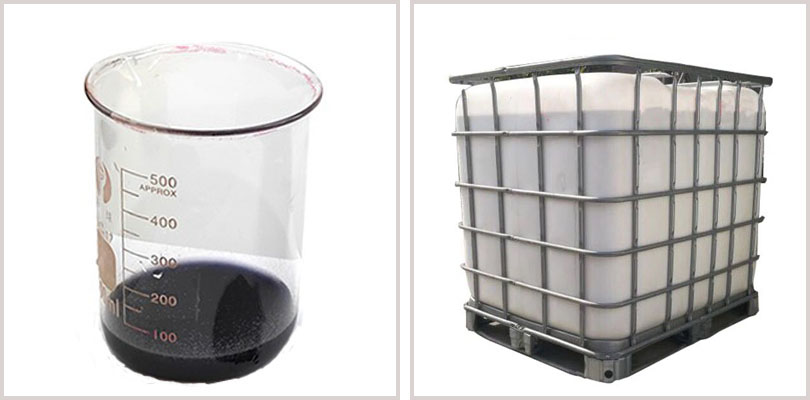

Cangzhou Xincheng Weiye Co.Ltd is one of the leading manufacturer of sulphur black in China, especially our Environment-friendly 100% Liquid Sulphur Black quality is even better than Archroma.

As dyeing is one the most important procedure of denim fabric production, our company have researched the denim fabric production process.

1. General production process of denim:

Spinning-winding-warping-indigo dyeing and sizing-weaving-singeing-sizing-weft-drawing-shrink-proof finishing-drying setting-finished products

Warp preparation: The warp preparation of jeans includes yarn twisting, winding, warping, warp indigo dyeing, sizing and warping.

(1) Yarn Twisting: In denim production, the warp and weft yarn, especially the warp and weft yarn with larger twist, should be wetted and heated to stabilize its twist.

(2) The purpose and requirement of twisting

Aim: To improve the quality of fabric by smoothly carrying out warping and dyeing and sizing processes, reducing weft shedding, weft shrinkage and looping during weaving.

Requirements: To stabilize yarn twist by increasing tension, wetting and heating, and to achieve a reasonable moisture regain of 8%~9%.

There are many processes for denim, such as singeing, singeing, shrink-proof and so on.

From the process described above, we can know dyeing with indigo blue and sulphur black is very important as it will have direct effect on the finished denim, so we should choose high quality indigo blue or sulphur black for our cotton yarn dyeing.

If you have such requirement, welcome to contact with us.

Post time: Jul-16-2019