Be sure to use ultra-fine powder dye for dyeing.

Dyes used for tie dyeing, with over 80% of dye particles having a diameter of less than 2 microns and no large particles present.

This is because the larger the particles of vat dye, the smaller the surface area per unit weight of the vat dye, and the smaller the reaction area in contact with the reducing solution. During steam reduction, the lower the reduction rate, the worse the degree of reduction dissolution. In continuous tie dyeing, the reduction and dissolution of dyes, as well as their diffusion and dyeing into the fibers, are completed in a short period of time (usually 60-90 seconds). Therefore, the speed of dye reduction and the quality of the reduction and dissolution state have a significant impact on the uniformity and penetration of dyes.

The poor penetrability of dyes inevitably leads to an increase in “floating color” and a decrease in color fastness. Especially the rubbing fastness.

Production practice has proven that the dye particles are small, the suspension of the pad dyeing is stable, not easy to precipitate, the dyeing penetration is also good, and the color yield is relatively high.

Choose vat dyes with low soap washing effect

The so-called soap washing effect refers to the change in the depth of the color of the dye dyed on the fiber after soap washing treatment.

Experiments have shown that most vat dyes have a significant “soap washing effect”.

The dye soaked and rolled on the fabric undergoes significant changes in color before and after soap washing through reduction and oxidation.

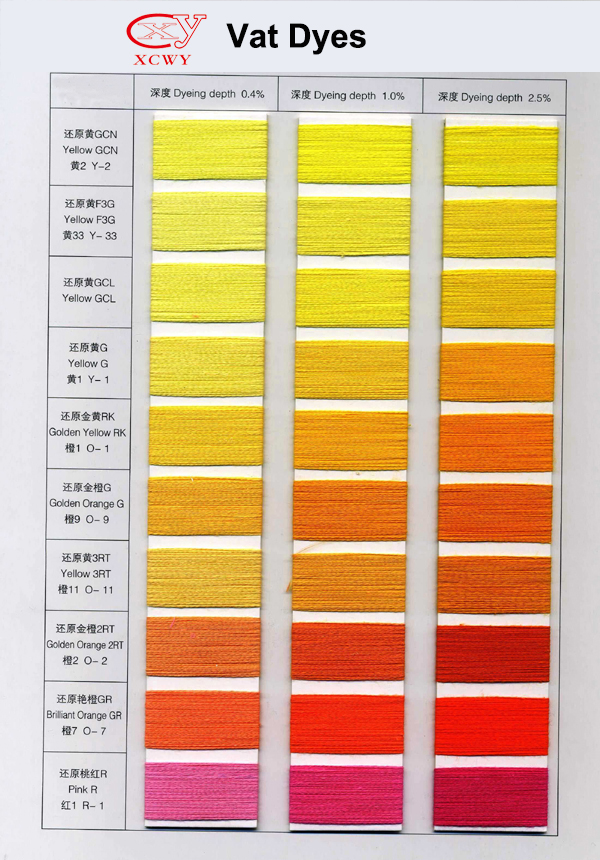

Cangzhou Xincheng Weiye Chemical Co., Ltd is the professional vat dyes factory, including vat orange 7, vat yellow 2, vat red 15, vat blue 4, vat brown BR and vat vioelt RR. Welcome your inquiry.

Contact person: Miss Jessie Geng

Email:jessie@xcwychem.com

Mobilephone/Whatsapp: +86-13503270825

Post time: Jan-21-2025