Spinning dye is a new dyeing technology that uses a spinning machine to uniformly add color masterbatch into fibers for dyeing.

This dyeing method does not require the dye to be dissolved in water, thus avoiding the problem of dye pollution of water sources, and is a relatively environmentally friendly dyeing method.

Advantages of spinning dyes

Uniform dyeing: Due to the addition of color masterbatch during fiber formation, it can fully penetrate into the interior of the fiber, resulting in relatively uniform dyeing without dead corners. The colorants are evenly dispersed in the fibers, have strong friction resistance, and are not easily faded.

High color fastness:

The dyed color has high color fastness and is not easily faded or discolored, even under harsh conditions such as high temperature, sunlight, and pollutants.

Environmentally friendly and pollution-free:

Since there is no need to dissolve dyes in water, it avoids the pollution of dyes to the environment and saves a lot of water resources.

Application fields of spinning dyes

Spinning dyes are widely used in various fiber materials, such as PET polyester fibers, polyester, PA6 nylon, polypropylene, etc. Due to its environmental friendliness and high efficiency, spinning dyes are also widely used in composite materials such as plastics, rubber, coatings, and inks. In addition, color masterbatch is also used in fields such as household appliances, electronic packaging, wire and cable, and food packaging.

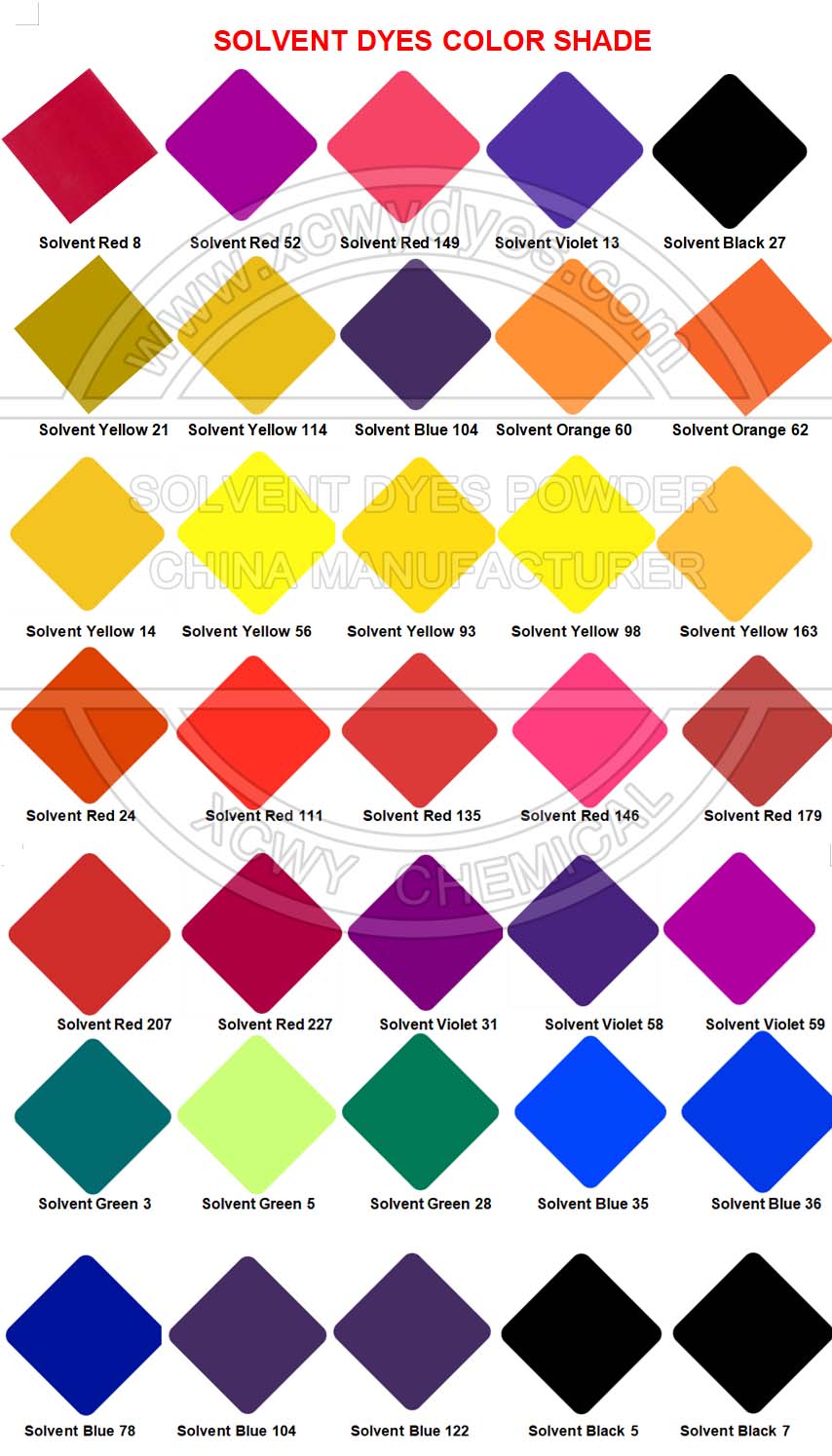

Cangzhou Xincheng Weiye Chemical Co., Ltd is specially producing solvent dyes used for pre-spinning coloring, including solvent blue dyes, solvent red dyes, solvent yellow dyes, solvent black dyes and solvent orange dyes. Welcome your inquiry.

Contact person: Miss Jessie Geng

Email:jessie@xcwychem.com

Mobilephone/Whatsapp: +86-13503270825

Post time: Feb-17-2025